Achieve clarity, control, and compliance in purchasing with Supplier Lifecycle Management

Times are tough for procurement. More risk, more rules, less time. Strategic buyers are contending with global tariff swings, geopolitics in crisis mode, shortages of critical raw materials, and rising ESG expectations. To keep up with changing circumstances, they have to actively manage and continuously adapt their supplier base.

Besides identifying and qualifying reliable suppliers, procurement teams must uncover and mitigate risks early. Also, they need to maintain full control over supplier approvals and classifications, all while ensuring traceability and compliance.

With SupplyOn Supplier Lifecycle Management, buyers have a clearly structured, automated process that streamlines supplier management. It generates tangible added value for purchasing, quality, risk management, and compliance teams.

The SupplyOn process explained step by step

1. Identify and pre-qualify suppliers

SupplyOn is the leading global supplier network for the automotive, aerospace, and manufacturing industries, connecting more than 140,000 companies. You are able to efficiently locate suitable business partners or seamlessly onboard existing contacts.

Your benefit: Fast, targeted supplier search based on verified data

Rather than starting from zero, you gain access to a broad and verified network within the SupplyOn supplier community.

2. Use customized qualification profiles

Qualification requirements vary by product group, region, division, or risk level. Supplier Lifecycle Management lets you define individual qualification profiles. Then it automatically creates questionnaires, verification documents, checks, and evaluation criteria, among others. All that without involving IT or having to search manually for up-to-date templates.

Your benefit: An automated and audit-ready qualification process

Everyone involved in the qualification process evaluates suppliers based on standardized criteria. This ensures consistent, transparent decisions. In case circumstances change, you can easily adjust or adapt your criteria.

3. Recognize risks at an early stage

Through the structured, context-sensitive process, the right information is automatically requested based on supplier type, location, and product group. This lets you identify and mitigate risks, whether financial, quality-related, or ESG-driven, before they can disrupt operations.

Your benefit: Informed supplier selection with minimized risk

Risks are systematically uncovered and evaluated. You can select reliable and strategically aligned suppliers based on solid data.

4. Ensure cross-departmental cooperation

Teams from procurement, quality, sustainability, risk management, and other business functions collaborate within a shared, role-based system. Tasks such as audits, risk assessments, and certificate reviews are automatically assigned, then deadlines are tracked and results centrally documented.

Your benefit: Clear responsibilities and smooth coordination

Everyone knows what to do and when. You eliminate duplication and avoid communication gaps.

5. Apply structured approvals and strategic classifications

Only authorized users can approve suppliers and assign strategic classifications, such as “preferred supplier” or “new business on hold.” Any changes, such as issues related to ESG or performance, can be immediately reflected in the classification status.

Your benefit: Confident decisions and traceable compliance

Approvals and classifications are based on accurate, reliable data and aligned with the company-wide sourcing strategy.

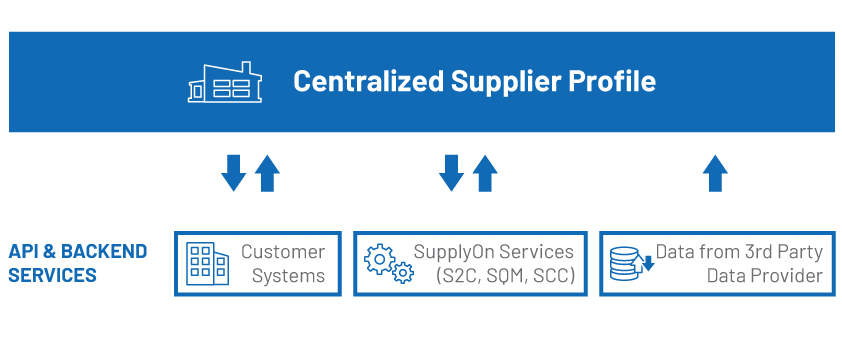

6. Maintain central data in the supplier profile

All relevant supplier information, including qualifications, evaluations, certificates, approvals, and classifications, is stored in a central digital profile. The data is always up to date and fully integrated across systems.

Benefit: Full transparency and control over supplier data

You no longer need to search through emails or spreadsheets. All supplier data and performance reports are readily accessible in one place.

Conclusion: Structure leads to success

SupplyOn Supplier Lifecycle Management is more than a software tool. It provides a tried-and-tested, structured and strategic process that ensures secure supplier selection, mitigates risk, and breaks down internal silos.

As members of a global network, potential suppliers become trusted, long-term partners who are transparent, compliant, and secure.