100% compliance in purchasing: from duty to high performance

As explained in my last blog article “Four steps to achieve 100% compliance in purchasing“, purchasing organizations that take the topic of compliance seriously should first create a solid basis with the introduction of standardized processes and tools in order to achieve company-wide transparency and consistency in their purchasing activities. This allows mandatory topics such as avoiding bribery or maverick buying to be brought under control.

Today’s world is more complex

But compliance today encompasses much more than the purely mandatory topics and has become significantly more extensive, complex and dynamic. Purchasing is ideally positioned for these new requirements thanks to its central role in the company.

Examples of the new requirements are:

- More comprehensive risk management in the supply chain

- Higher requirements for IT security and data protection

- New legal requirements, which can vary greatly from country to country

For example, the Supply Chain Due Diligence Act or Conflict Minerals Reporting based on the Dodd-Frank Act - Sanctions

For example, in the case of violations of the human rights of Uyghurs - Constantly increasing requirements from customers or from our own product marketing

For example, the reduction of the CO2 footprint

The good news is: to address these new challenges, you can build on solutions that are already in place. The core processes of purchasing, which are already digitized today, can be relatively easily supplemented with further needs from compliance and risk management.

In this context, it is not only important that all relevant departments internally, i.e., quality assurance, logistics, product development, data and security management, compliance management, etc., are involved in the processes, but also that the results of these processes are available for strategic purchasing decisions. For this to succeed, purchasing must become active at an early stage and needs access to these other areas.

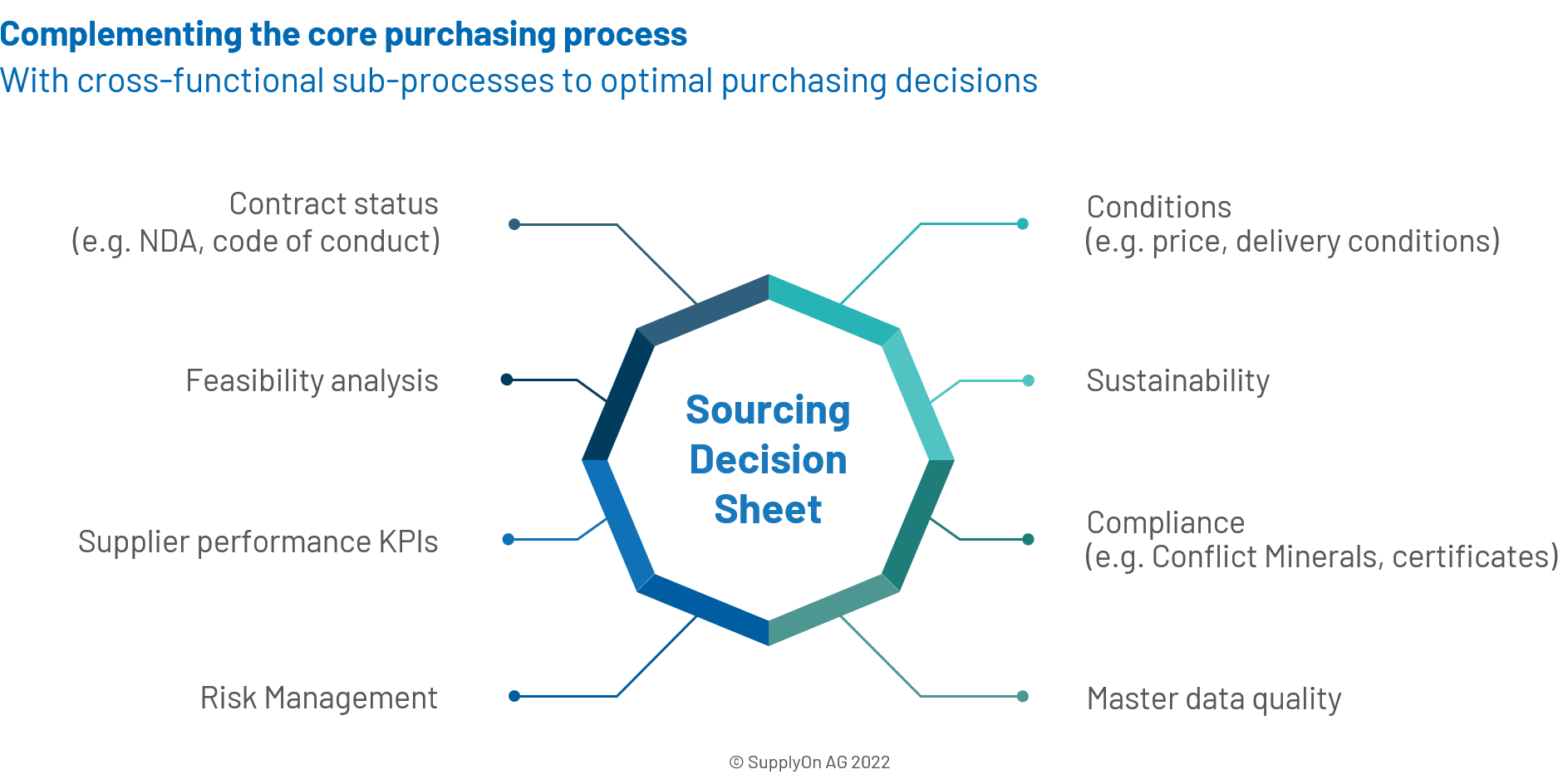

Key player: the Sourcing Decision Sheet

As in my last blog article, I would like to explain the practical implementation using our customer Continental Automotive as an example. Just as for the Rfx process, uniform processes and software tools were defined for the various compliance topics and made available via the SupplyOn solutions. The aim here is also to involve suppliers at an early stage and to provide them with central access via SupplyOn to maintain the necessary information.

At Continental Automotive, the so-called Sourcing Decision Sheet, which forms the basis for decision-making by the Purchasing Council at Continental and which used to be based primarily on price and conditions, has been and will continue to be successively supplemented with information from the various compliance aspects. As a result, these are also automatically taken into account in the supplier selection. The decisions made by the strategic purchasing committee are in turn recorded and documented centrally in the tool.

Here are some examples of data that automatically flows into Continental Automotive’s Sourcing Decision Sheet from non-purchasing areas:

- Risk Management: Suppliers of production material must include in their bids all locations that will be relevant for the production of the requested parts. Based on their geo-location, all specified locations are automatically classified and assigned to the risk categories specified by Continental.

- Supplier Assessment: Performance data is already available for suppliers with whom Continental Automotive has been working for some time — both at site and commodity level.

- Feasibility Study: For new parts to be developed, feasibility analyses with regard to technology, quality and logistics are carried out in parallel with the sourcing process with the suppliers in question. This process is supported by the SupplyOn Technical Review service.

- Certificates: All suppliers are required to enter their status for standard industry certificates in the SupplyOn Business Directory. Depending on the certificate type, availability is sometimes even a mandatory prerequisite for being awarded a contract.

- Compliance: Adherence to guidelines and regulations can be flexibly queried from the supplier or alternatively integrated from external data sources or customer systems.

All these different aspects flow into the Sourcing Decision Sheet and generate a holistic picture based on formulas and weightings that can be defined freely. Purchasing thus has a flexible and scalable tool at its disposal for effortlessly mastering all aspects relevant to procurement. This means that purchasing is well equipped not only for current challenges, but also for those of the future.

Action recommendations at a glance

In summary, here are the steps that should be followed in order to cover all aspects and achieve 100% compliance in purchasing:

The duty

First of all, it is necessary to introduce uniform and company-wide binding core processes that are anchored in the organization via suitable tools. In this context, increasing master data quality is a very important aspect. High data quality is a prerequisite for any kind of digitization and thus a homework assignment for all organizations involved. The good news is that digitization not only requires high master data quality, but also supports and enables it.

The extra mile for even higher performance

The extra mile consists of supplementing the core aspects in the award process — i.e., price and conditions — with all aspects of a 360-degree compliance management process and integrating these into the strategic decision-making process.