Four steps to achieve 100% compliance in purchasing

Compliance — this buzzword is currently being used in an almost excessive manner. Today, everything and everyone must be “compliant”: Every company, every single employee from the assembly line worker or the clerk to the management, as well as suppliers and service providers.

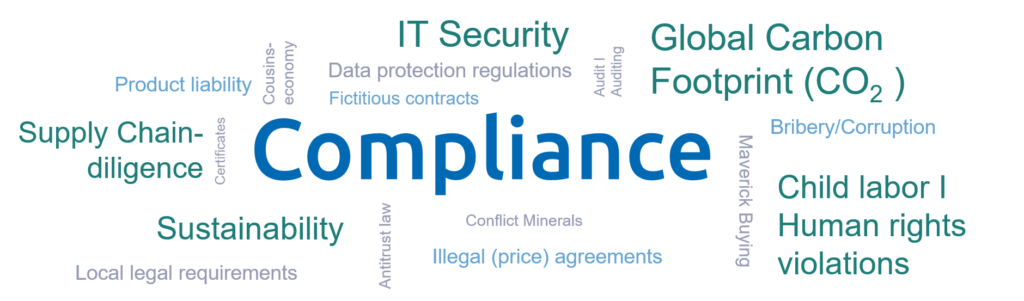

The fact that quite diverse topics are encompassed under the term compliance increases the complexity. These include, for example:

The fact that quite diverse topics are encompassed under the term compliance increases the complexity. These include, for example:

- Sustainability

- IT security

- Data protection

- Global Carbon Footprint

And — most recently — the so-called Supply Chain Compliance Obligations Act, often abbreviated simply to Supply Chain Act, which will become mandatory for companies with more than 3,000 employees on January 1, 2023, giving the topic additional explosive power.

But what does compliance really mean? If you look it up on Wikipedia, it is primarily a matter of adherence to standards, regulations, and other requirements, i.e. compliance with applicable laws as well as company-specific specifications. Purchasing plays a decisive role here as the central organization and interface to suppliers and partners.

A look back — how it all began

About ten years ago, the topic of compliance in purchasing was more manageable. At that time, it was primarily about avoiding agreements with preferred partners, bribery, and maverick buying — in other words, buying that bypassed the purchasing department.

A common approach to creating greater transparency and preventing undesirable behavior was, and still is, the introduction of electronic procurement solutions, with the help of which processes, contracts and master data could be centralized and standardized.

A practical example

To ensure 100% compliance in purchasing, Continental Automotive made use of our sourcing solution, which offers purchasing organizations an optimal technological foundation for introducing rule-compliant processes. But a suitable tool is only part of the deal. A tool is only effective if it is consistently implemented, anchored throughout the company, and used by everyone, i.e., if the underlying business processes are adapted and lived consistently. To this end, Continental Automotive proceeded according to the following 4-step plan:

To this end, Continental Automotive proceeded according to the following 4-step plan:

- In the first step, a central purchasing organization was established, which was entrusted with global responsibility for processes and tools in purchasing.

- In the next step, this organization developed uniform processes that are binding throughout the corporation in all regions.

- To ensure that these processes are adhered to and to make it virtually impossible to go through purchasing processes in any other way, uniform software tools were selected and configured. For tenders and the award process, the decision was made in favor of SupplyOn Sourcing.

- The last step was the most complex and extensive, as it was now not only a matter of training the global purchasing organization, but also of integrating and supporting the suppliers in the change process. During a certain transition period, parallel processes were still tolerated and only punished with a yellow card. Once this introductory period had ended, parallel processes were no longer accepted and, in case of doubt, the red card was shown. From this moment on, the use of the standard process was mandatory to get an order.

With the consistent implementation of standardized processes and tools in purchasing, Continental has created a solid foundation. This is the mandatory program that every company seeking to be compliant in purchasing should undergo.

In my next blog article, “100% compliance in purchasing: from duty to high performance“, I will describe how this basis can be used to create a comprehensive compliance management system.