Seven success factors of supplier onboarding

There is much more behind the connection of suppliers to the SupplyOn platform than just the technical rollout, which involves sending registration links for logging onto the SupplyOn portal. Rather, onboarding is an overall process consisting of various components.

It all starts with developing onboarding and communication concepts. The next step is to prepare the information in the Supplier Info Portal. This is followed by the technical rollout, in which the supplier is also supported by call centers during registration. All of these steps are performed one after the other in order to make the change management at customer and supplier as successful and smooth as possible.

The recipe for a successful supplier connection is equally simple and promising. In the following article you will learn about the seven “ingredients” that make the supplier onboarding process a success.

#1 Always keeping the goal in mind

Introducing collaboration solutions such as SupplyOn entails more than the mere implementation of new software by the customer. Rather, it is about the sustainable collaboration of business partners. Unless suppliers make extensive use of the software, there is no business case. It is always about both parties, the customer and the supplier. This is a fact, all those involved in the onboarding project always keeps in mind. Thus, the focus strongly is on usage on the supplier side (supplier commitment, supplier engagement and supplier usage).

#2 Providing sufficient capacities and resources

As a result, supplier onboarding should be approached with the same priority and commitment as implementation. To ensure that this topic receives the appropriate attention and appreciation, we recommend that the customer allocates resources to it and forms a dedicated project team. This then selects the suppliers according to predefined qualification criteria. Those selected suppliers will jointly drive the digitization strategy with the customer in the future. Here again, the rule applies: there is no business case without supplier usage.

#3 High customer commitment in the onboarding process

A further success factor is the commitment of the purchasing organization. In our experience, the more rigorously you pursue the digitization strategy, including roadmap and timeline, the higher the onboarding rate. Both, top management and operational commitment play a key role. We recommend that purchasing companies introduce the digitization initiative with SupplyOn to their suppliers through personal contact. We then get things rolling by inviting the suppliers to use the platform. In other words, the customer introduces suppliers to the platform and then SupplyOn employees take over and support them in the registration process.

#4 A large proportion of already registered suppliers

In the 20 years since its foundation, SupplyOn formed a huge global network of around 100,000 companies on its platform. It is therefore very likely that many suppliers are already working with SupplyOn. They are familiar with the registration process and already know the solutions in place. In our experience, success rates are very high for those suppliers who already work with other business partners via the platform.

#5 Putting the customer in the supplier’s shoes

Before a supplier is actually connected, test runs are carried out first. By default, the onboarding process starts with the customer logging on to a test landscape created for this purpose. This simulates the role of the supplier which the customer now takes on. The customer thus gets a clear view of the future collaboration. From our experience we know: The more detailed you simulate the supplier view, the stronger the adoption of the digital solution. After evaluating the test results and successfully testing the overall process, the solution can now go live and onboarding can begin.

#6 Transparent registration process

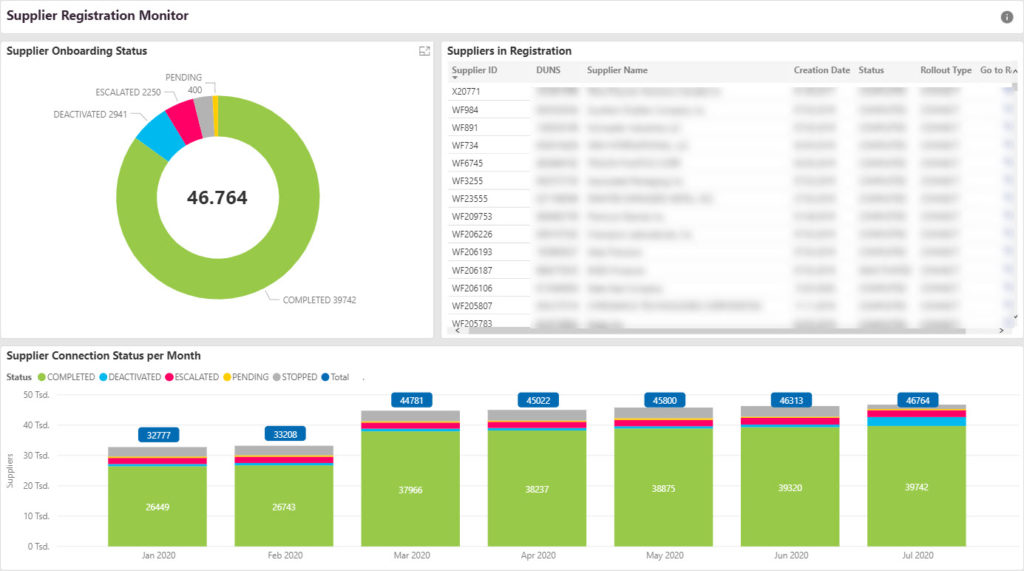

Transparency is crucial during the onboarding process. It is about staying on top of all activities and their results. SupplyOn therefore not only contacts suppliers proactively but also works with an experienced call center. The trained call center agents assist suppliers with the registration process and answer any questions that may have remained unclear. After 28 days, we conduct a handover with the customer. This allows the customer to see which companies have been successfully connected and which have not. During this process, our call center agents document all activities in writing. The customer can view these via the SupplyOn platform and seamlessly initiate final clarifications.

Beyond the onboarding quota, the customer can also check whether and to what extent the digital process is adopted by all parties involved. Clearly arranged dashboards provide detailed usage reports.

All these measures ensure transparency and onboarding quality—and they clearly set us apart from the competition.

#7 Support: Providing various information channels

Upon completion of the onboarding process, we continue to care for the supplier’s information needs. There are a variety of tools at his disposal to familiarize with the platform. These range from free tutorials to information or training sessions to the Supplier Info Portal. This portal is specifically tailored to each customer. Suppliers can view all relevant content here: general project information, instructions for registration, help on various solutions, guidelines and policies. Particularly valuable are the personal introductory videos of the customer’s C-level (CPO or CEO), in which they explain the digitization initiative and its goals.

The result: Efficient collaboration via digital communication processes

Once the supplier is connected, the business relationship between the partners will be different. We think it is important that the customer takes the initiative towards the suppliers for using these new communication channels and jointly embarking on the path of digitization. For a sustainable change in the business relationship, we recommend you consider the seven success factors listed above and define the next steps for a joint digital future. After all, efficient digital processes strengthen and secure long-term collaboration between business partners.