Sourcing Cycle Time: Why RFx-to-Award decisions take too long

Sourcing cycle time describes the time between an RFx and the final award decision. In direct materials sourcing, this RFx-to-award phase is where delays most frequently occur – and where negotiated savings quietly erode.

Savings rarely disappear at the negotiation table. They disappear in the weeks between RFx and award, when prices shift, capacities change, engineering updates arrive, approvals stall, and evaluations are revisited. As sourcing cycle time expands, organizations are exposed not only to cost erosion, but also to increased launch, quality, and supply risk.

The objective is therefore not simply to award faster, but to shorten the RFx-to-award phase without compromising quality or increasing risk, ensuring that award decisions are complete, auditable, and execution-ready from the outset.

Why RFx-to-Award decisions take too long

Sourcing teams are seldom slow because they lack capability or intent. Delays emerge because award decisions depend on inputs that are fragmented across functions, systems, and approval paths.

Evaluation work often expands as bid versions multiply, clarifications arrive late, and changes are introduced mid-process. Quality and risk checks are frequently conducted outside the sourcing workflow, which means findings arrive after commercial decisions have already been shaped. Approval steps remain manual and sequential, relying on email loops and individual follow-ups rather than governed decision paths. Finally, award decisions do not always translate cleanly into supplier qualification and quality readiness, creating friction at the handoff.

As these issues accumulate, sourcing cycle time increases, decision confidence declines, and downstream disruption becomes more likely.

Why long sourcing cycle times increase cost and risk

Extended RFx-to-award phases create exposure precisely at the point where sourcing decisions should be most stable.

Negotiated savings lose validity as market conditions and supplier capacities evolve. Quality requirements addressed too late lead to corrections after the award, when changes are costly and difficult to absorb. Qualification and readiness gaps surface only once execution begins, increasing the risk of launch delays or supply interruptions.

In direct materials sourcing, these effects are not abstract. They materialize during execution—often when options to correct them are already limited.

How to reduce sourcing cycle time without increasing risk

Shorter sourcing cycle times are not achieved by reducing diligence. They are achieved by integrating decision-relevant checks directly into the sourcing workflow, so the award decision is complete at the moment it is made.

The “Fast + Safe” award model

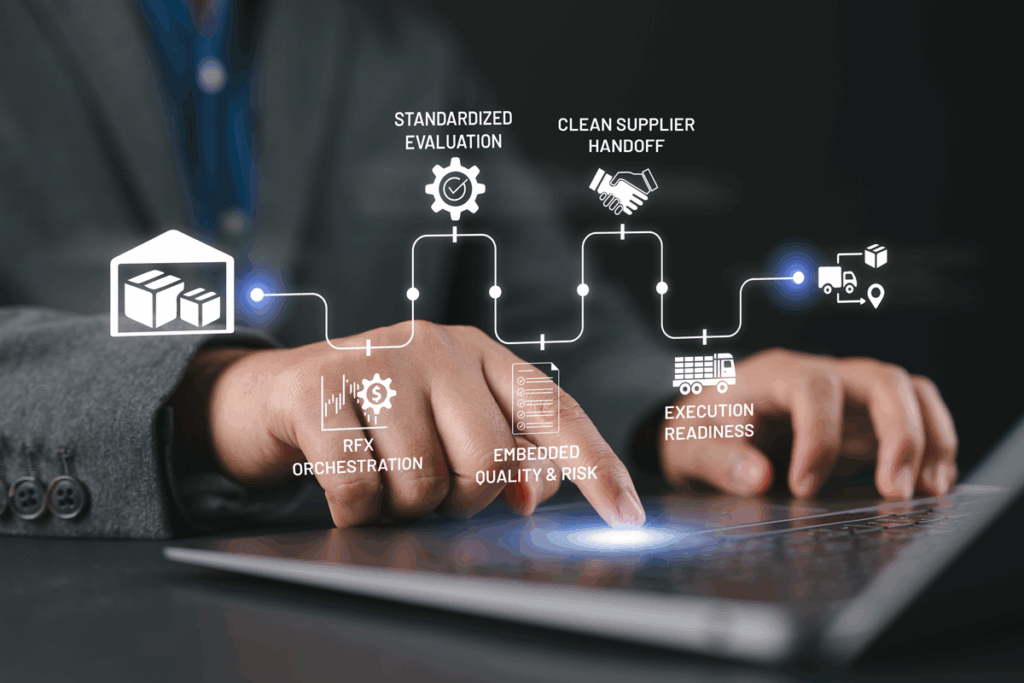

To shorten RFx-to-award timelines without increasing exposure, sourcing teams need a model that combines speed with decision integrity:

- Digitize operative sourcing end to end (RFx → evaluation → award) to create a single, continuous workflow

- Standardize decision criteria so award decisions are repeatable, auditable, and comparable across regions and teams

- Embed quality and risk assessments directly into the sourcing decision instead of adding late-stage gates

- Automate administrative effort, such as evaluation structures and decision documentation, to remove cycle-time drag

- Connect award decisions to downstream readiness, including qualification and quality gates, so execution risks do not surface later

This approach reduces rework, shortens RFx-to-award timelines, and preserves decision quality.

Why manual sourcing extends cycle time

Many sourcing delays persist not because teams lack expertise, but because critical decision steps remain manual or disconnected.

When evaluations, approvals, and quality inputs are handled outside a governed workflow, decisions stall. Evaluations are revisited instead of finalized, approvals progress sequentially through email chains, and quality and risk inputs arrive too late to shape the outcome. Teams compensate with rework rather than confidence, extending the RFx-to-award phase and increasing downstream exposure.

Manual sourcing does not fail due to lack of effort—it fails because decisioning is not structurally supported.

What governed, faster award decisions enable

Predictable RFx-to-award timelines.

Defined workflows replace ad-hoc coordination, making award timing reliable rather than dependent on individual follow-ups.

Higher decision confidence at the point of award.

When commercial, quality, and risk criteria are evaluated together, awards are made based on complete information, reducing the need for post-award corrections.

Fewer late-stage stoppages.

Integrated approvals and embedded checks prevent unforeseen blockers from emerging after the award, when delays are most costly.

Smoother transition into qualification and execution readiness.

Because readiness requirements are already reflected in the award decision, supplier handoff becomes cleaner and faster.

Why SupplyOn for direct materials sourcing

SupplyOn is designed specifically for direct materials sourcing in manufacturing environments, where award speed and decision integrity are closely linked.

Its supplier network supports rapid engagement at scale, with more than 140,000 registered suppliers for production material across over 160 countries. Standardized and governed RFx processes reduce friction in evaluation and approval, while integrated quality and risk decisioning ensures that fast awards are not blocked later. Automation and AI reduce operational effort in evaluation and documentation, addressing one of the most persistent sources of award delay.

Together, these capabilities support faster awards without weakening governance or execution readiness.

Customer Example: Sourcing at scale with measurable adoption

SMS group implemented end-to-end sourcing processes including eAuctions and RFx. Today, the organization conducts more than 9,000 eAuctions and approximately 3,500 eRFx annually, involving over 4,000 material suppliers. The scale of adoption illustrates how governed, integrated sourcing processes support both speed and consistency in award decisions.