Supply Chain Risk Management – far more than just getting out of the current crisis

The current coronavirus crisis clearly shows how vulnerable and susceptible to disruption supply chains are today. It also shows how important it is to anticipate disruptions of any kind in order to minimize their impact. In this context, supply chain risk management plays a major role. Essentially, it is a matter of finding answers to the following questions:

- What risks is my supply chain exposed to?

- How can I identify problems in my supply chain as quickly as possible, catchword early warning system?

- What do I need to do to minimize loss and to be even stronger in the end?

- As well as the lessons learnt: Which measures should I implement to ensure that I can effectively respond to any future risks?

Supply chain risks: what you need to consider

Supply chain managers know that non-orderly deliveries are less of an exception than they want. This is due to the multitude of risks that can lead to interruptions within a complex supply chain:

- External risks: Natural disasters such as earthquakes, volcanic eruptions, storms, pandemics

- Sociopolitical risks: strikes, border closures, trade barriers

- Individual risks: insolvencies, loss in reputation

- Process-related risks: information gaps, delayed identification of deviations, inadequate process compliance

- Volatility: unexpected changes in demand or at transport hubs

It is therefore essential for holistic risk management to consider supply chain risks end-to-end and not just focus on individual risks.

Time is the decisive factor

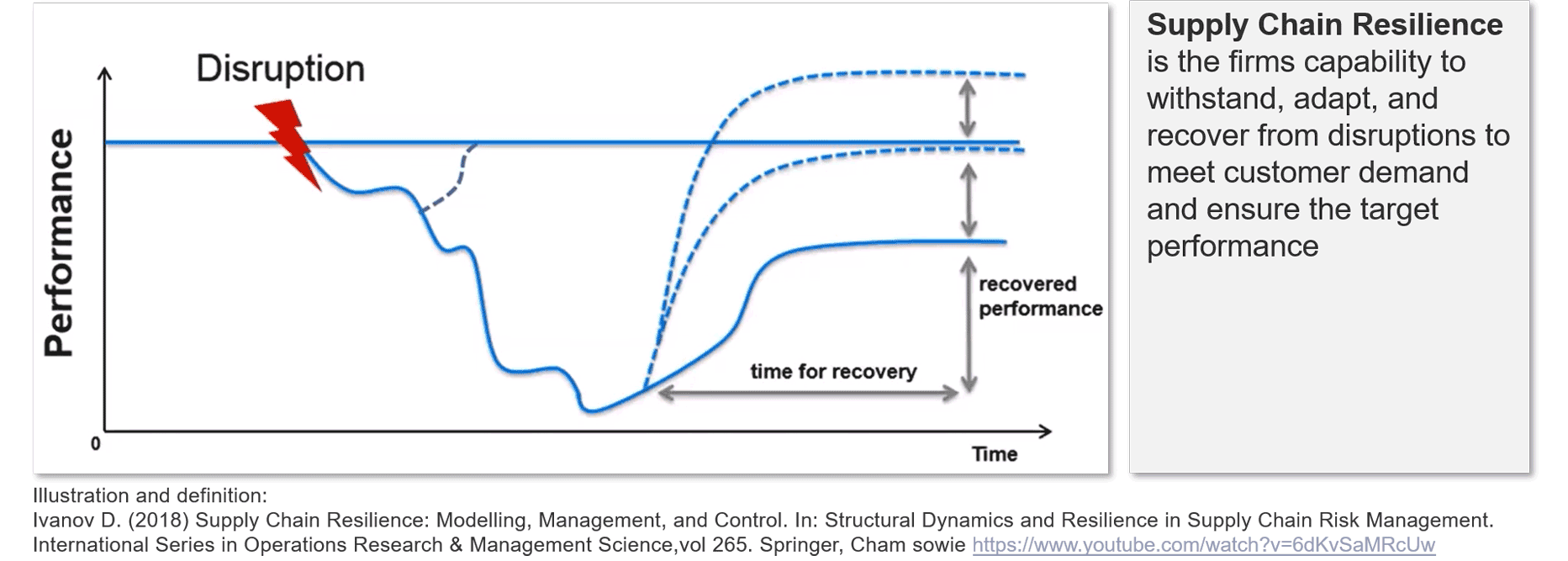

In crises, cards are reshuffled: Every crisis brings forth winners and losers. That is because in every crisis a new distribution battle starts. It is won by the company that is best prepared. Time is the decisive success factor here: the faster a company gets back on track, the bigger its chances of emerging from the crisis unscathed or possibly even stronger.

Close integration of risk management and supply chain management

An important aspect when dealing with crises is not to look at risk management separately, but to see it as an integral part of supply chain management. Of what use are the best emergency plans for my production if these plans come to a standstill because my suppliers are unable to deliver or transports are disrupted? To minimize my risks, I also have to consider the risks to which my business partners—above all my suppliers and transport service providers—are exposed.

In this context, the following two perspectives are important:

- Preventive

What risks is my supply chain exposed to? How would that impact me? What steps do I need to take to avoid or minimize the effects? - Operational, if there actually is an incident

What are the effects and how severely am I hit by these? Who of my business partners are affected and to what extent? How can I minimize damage or losses?

Companies that digitized their supply chain and connected their suppliers well before an acute crisis, are clearly at advantage: they have already laid the foundation to leverage the time factor. They get an overview of the situation with just a few clicks and can then immediately respond accordingly. Everything you do in ‘normal’ times in terms of strategy, tools and processes to optimize and stabilize your supply chain pays off even more during a crisis.

The next crisis is just around the corner

Perhaps you also got the feeling that the worst is already behind us: Production in China has largely been ramped up again. In Europe, too, the situation is easing. Stock markets worldwide seem to be recovering. Yet the crisis is far from over. The number of infections continues to rise dramatically worldwide. Again and again, local hotspots are emerging even in countries that have the situation largely under control. The threat of a second wave—and thus a second lockdown—is still very real. In addition, interrupted supply chains and transports cannot be restored at the push of a button.

This high level of uncertainty seems to be the ‘new normal’ that we have to learn to deal with. Even before there was a coronavirus crisis, there was talk about living in a VUCA world (volatility, uncertainty, complexity, ambiguity). A world that is becoming increasingly unpredictable, and in which situations arise that were previously thought impossible.

From SupplyOn’s perspective, supply chain risk management is not a trend topic whose significance will diminish once a vaccine or treatment for COVID-19 has been found. We are convinced that the efficient management of supply chain risks will become even more important in the future to successfully master the growing challenges of an increasingly complex world.

With this series of blog articles, I would like to highlight the numerous aspects and levels of holistic supply chain risk management. Using practical examples, I am also going to present pragmatic approaches for successfully managing supply chain risks and for designing robust supply chains. Over the next few weeks, I am going to address the following topics:

- Which immediate actions do I need to implement to successfully steer my supply chain through an acute crisis?

- What measures and processes help to make supply chains resilient in the medium and long term?

- Which lessons does this coronavirus crisis hold for organizations to get out of it in an even stronger position?