It’s high time to tap the potential of the 4th Industrial Revolution

COVID-19, its effects on the industry and the restart of production currently dominate on the agenda. Everyone is longing for a return to normality and this will be the case in a few months’ time. The world will not stand still and it is certainly not standing still at this very moment.

The pace of automation and digitization accelerates

Various companies are currently seizing the opportunity to actively shape the future and drive digitization in their own companies. The crisis has shown how vulnerable supply chains and production are due to the loss of human labor. Thus, many companies are now thinking about how automation can reduce this susceptibility. It may sound cynical to read in some comments that robots do not get sick. But ultimately, we will see the crisis accelerating automation and digitization.

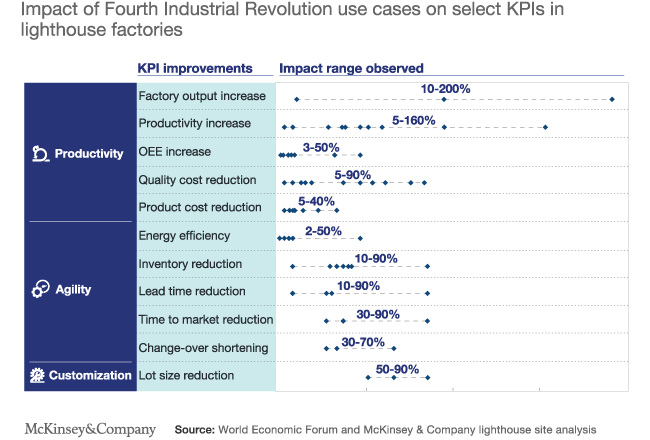

This is hardly surprising when you look at the KPIs in “Lighthouse Factories”:

Industry 4.0 boosts productivity

We are seeing a significant increase in productivity and cost optimization in all factory areas through the use of Industry 4.0 solutions. SupplyOn supports this digitization with its Production-to-Supply suite. The solution consolidates capacity, production and quality data, thus providing entirely new insights of weak points and (in)efficiencies. By leveraging AI, machine learning and predictive analytics methods, Production-to-Supply evaluates the vast amount of data more precisely and reliably at a much quicker speed than any human being.

Production-to-Supply increases supply chain reliability

The Production-to-Supply solution also meets the trend towards deglobalization. Deglobalization already began in 2008/2009 with the financial crisis. There, the vulnerability of production and supply chains became obvious. Since then, attempts have been made to increase stability, reliability and resilience. However, this also makes it clear that “deglobalization” does not mean a full relocation of all production facilities to the domestic markets.

Closer relations between buyers and suppliers

Along with deglobalization comes the establishment of more closely and strongly connected production and supply processes. As a result, the relationship between supplier and customer will collaborate much closer. This in turn means that data integration into the respective systems will increase considerably.

SupplyOn supports this development with Production-to-Supply: from sales planning to parts production, all data can be integrated across company boundaries, evaluated using sophisticated analytics and the results then made available to all those involved in the process. This also enables small and medium-sized companies to take advantage of the new opportunities offered by digitization at low financial and organizational cost.