Eliminating the blind spot: Insights into supplier’s production reduce inventories, lower risks & save costs

A leading aerospace company optimized its global supply chain with SupplyOn through an innovative Industry 4.0 project: integration of the supplier’s MES (Manufacturing Execution System) gives both customer and supplier a virtually real-time, joint view of the supplier’s situation – in terms of demand, stock and production. Replenishment planning is checked against customer requirements, i.e. production orders against stocks. The result is transparency and trend feedback – enabling stock reduction and increased supply reliability.

The challenge

The aerospace supply chain is globally distributed, its various stages tightly coordinated. What is more, the complex components have to meet rigorous requirements and production times are very long. Meanwhile the end customers – i.e. the airlines – enjoy enormous flexibility and variety in terms of customization, even shortly before delivery. The resulting change management takes effect along the entire supply chain, starting with the OEM. Technical component updates and short-term changes in demand are routine occurrences. In view of these challenges, stock buffers are traditionally created throughout the supply chain so as to ensure delivery to the end customer.

For this reason, one leading aerospace company was in search of a solution to reduce stocks while at the same time maintaining full supply reliability on its inbound supply chain.

Essentially, there were three questions to be answered:

- Is supply planning – especially supplier production – ideally synchronized with customer demand?

- Are the parts manufactured in time?

- What trends are there in terms of planning parameters such as replenishment period and production output that would help place the order with the supplier in time?

The solution: Connecting supplier MES to analytics solution

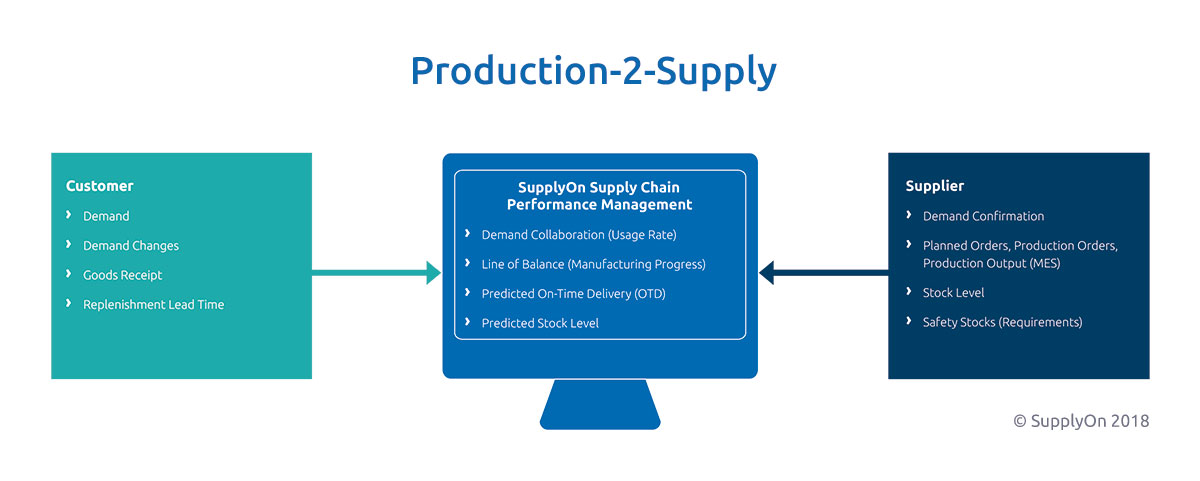

The company has been using the SupplyOn industry solution AirSupply for several years. So it was an obvious choice to add SupplyOn’s Analytics solution, since this answers all the above questions. The demand and supply processes in AirSupply are integrated with SupplyOn Visibility – Analytics – Intelligence. In this Industry 4.0 project, production orders and stocks are added into the analytics solution as data objects. The project involved an agile approach: the new solution was introduced and piloted in operational conditions within a period of just 90 days.

The pilot project initially involved a selection of components that are suitable for analyzing and forecasting demand and production planning: parts that are complex to produce or not easy to replace, with high safety stocks or irregular production output. The supplier inputs the planned orders, production orders and stock information into SupplyOn Analytics via various channels (web service, mobile app, EDI).

- Virtually in real-time, the analytics function calculates the bilaterally agreed KPIs to optimize collaboration:

- Demand Collaboration (Usage Rate)

- Line of Balance (Manufacturing Progress)

- Predicted On-Time Delivery (OTD)

- Predicted Stock Level

This then allows SupplyOn Analytics to analyze key supply chain planning parameters such as planned lead time and safety stocks, successively adapting them in the customer’s ERP system and the supplier’s production planning system.

The benefits

- Synchronizing demand and changes in demand with production progress and the stock situation enables optimized call-offs and reduced safety stocks. Trend assessments provide crucial support.

- Effective supply chain management depends on a holistic view of the entire process – right the way through from the preview and subsequent changes to demand and call offs, production, safety stocks, delivery and goods receipt by the company. Exception-based action is reduced to the truly critical situations and trends.

- Automated calculation of KPIs as agreed on by the customer and supplier saves time, as well as avoiding individual interpretations.

- Trend assessments help those involved intervene early on, thereby saving costs and maintaining supply reliability at a consistently high level.

- Joint view of the same operating figures makes for a high degree of supplier acceptance. Straightforward supplier integration by means of an industrialized on-boarding service. The supplier can send the data to Visibility & Analytics by EDI, web service or mobile app.

[Update – Dec 6, 2018]:

This use case clearly illustrates the growing importance of multi-tier supply chain ecosystems like SupplyOn for driving innovation, customer centricity and cost efficiency. At its core, it is all about end-to-end visibility across company walls. We are proud the be recognized as a Leader in Gartner´s new 2018 Magic Quadrant on Multienterprise Supply Chain Business Networks, which – in our perspective – is proof of the importance and validity of these digital ecosystems for corporate success.